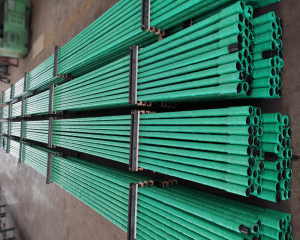

Nkọwa ngwaahịa

Mkpado ngwaahịa

| Nha aha | 5/8 nke. | 3/4 nke anụ ọhịa. | 7/8 nke. | 1 in. | 1-1/8 nke anụ ọhịa. |

| n'ime. | mm | n'ime. | mm | n'ime. | mm | n'ime. | mm | n'ime. | mm |

| Ngwakọta mkpanaka sucker zuru oke,njikọ mkpanaka a na-ehicha nha nha zuru oke na njikọta nke obere nha zuru oke. |

ODª

Akụkụ dị n'èzí | Nha | 1.5 | 38.1 | 1.625 | 41.28 | 1.812 | 46 | 2.187 | 55.6 | 2.375 | 60.33 |

| | | | | | | | | | | |

| Ndidi | 0,005 | 0.13 | 0,005 | 0.13 | 0,005 | 0.13 | 0,005 | 0.013 | 0,005 | 0.13 |

| | -0.01 | -0.25 | -0.01 | -0.25 | -0.01 | -0.25 | -0.01 | -0.25 | -0.01 | -0.25 |

| | | | | | | | | | | |

| Nha | 4 | 101.6 | 4 | 101.6 | 4 | 101.6 | 4 | 101.6 | 4.5 | 114.3 |

| Lª | | | | | | | | | | | |

| Ogologo | Ndidi | 0.062 | 1.57 | 0.062 | 1.57 | 0.062 | 1.57 | 0.062 | 1.57 | 0.062 | 1.57 |

| | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| D2ª | Nha | 1.365 | 34.67 | 1.49 | 37.82 | 1.677 | 42.6 | 1.99 | 50.55 | 2.177 | 55.3 |

| Opekempe | | | | | | | | | | | |

| D3ª; | Nha | 1.11 | 28.19 | 1.253 | 31.83 | 1.378 | 35 | 1.566 | 39.78 | 1.753 | 44.53 |

| | | | | | | | | | | |

| Ndidi | 0.015 | 0.38 | 0.015 | 0.38 | 0.015 | 0.38 | 0.015 | 0.38 | 0.015 | 0.38 |

| | -0.055 | -1.39 | -0.073 | -1.85 | -0.073 | -1.85 | -0.073 | -1.85 | -0.073 | -1.85 |

| BC1ₑ Maximun | Nha | 0,0625 | 1.59 | 0,0625 | 1.59 | 0,0625 | 1.59 | 0,09375 | 2.38 | 0,9375 | 2.38 |

| Njikọ mkpanaka Slim Hole Sucker, Slim Hole Polished Rod Coupling na Slim Hole Sub-Coupling |

| Nha | 1.25 | 31.8 | 1.5 | 38.1 | 1.625 | 41.3 | 2 | 50.8 | |

| ODª | | | | | | | | | | |

| Akụkụ dị n'èzí | Ndidi | 0,005 | 0.13 | 0,005 | 0.13 | 0,005 | 0.13 | 0,005 | 0.013 | |

| | -0.01 | -0.25 | -0.01 | -0.25 | -0.01 | -0.25 | -0.01 | -0.25 | |

| Nha | 4 | 101.6 | 4 | 101.6 | 4 | 101.6 | 4 | 101.6 | |

| Lª | | | | | | | | | | |

| Ogologo | Ndidi | 0.062 | 1.57 | 0.062 | 1.57 | 0.062 | 1.57 | 0.062 | 1.57 | |

| | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| D2ª | Nha | 1.177 | 29.9 | 1.427 | 36.25 | 1.552 | 39.42 | 1.927 | 48.95 | |

| Opekempe | | | | | | | | | | |

| Nha | 1.09 | 27.69 | 1.253 | 31.83 | 1.378 | 35 | 1.566 | 39.78 | |

| | | | | | | | | | |

| D3ª | Ndidi | 0.015 | 0.38 | 0.015 | 0.38 | 0.015 | 0.38 | 0.015 | 0.38 | |

| | -0.035 | -0.89 | -0.073 | -1.85 | -0.073 | -1.85 | -0.073 | -1.85 | |

| BC1ₑ Maximun | Nha | 0,03125 | 0.79 | 0,03125 | 0.79 | 0,03125 | 0.79 | 0,03125 | 0.79 | |

| a Dị ka e gosiri na ọnụ ọgụgụ C.1 |

| b Nha aha nke njikọta bụ otu nha ka mkpanaka sucker |

| Ngwakọta kemịkalụ |

| AISI | C | Si | Mn | P | S | Cr | Ni | Mo | V | Cu | Al |

| 1541 | 0.36-0.45 | 0.15-0.35 | 1.35-1.65 | ≤0.04 | ≤0.04 | ≤0.3 | ≤0.35 | ≤0.06 | 0.04-0.09 | ≤0.35 | ≤0.035 |

| 5140 | 0.38-0.45 | 0.17-0.37 | 0.4-0.7 | ≤0.025 | ≤0.025 | 0.8-1.1 | ≤0.3 | / | / | ≤0.2 | / |

| 4135 | 0.32-0.40 | 0.17-0.37 | 0.4-0.7 | ≤0.025 | ≤0.025 | 0.8-1.1 | ≤0.3 | 0.15-0.25 | / | ≤0.2 | / |

| 4120 | 0.17-0.24 | 0.17-0.37 | 0.4-0.7 | ≤0.025 | ≤0.025 | 0.8-1.1 | ≤0.3 | 0.15-0.25 | / | ≤0.2 | / |

| Ike Tensile (MPa) | Ike Mpụta (MPa) | Ogologo oge

(%) | Mbelata Mpaghara (%) |

| ≥655 | ≥405 | ≥16 | ≥48 |

| Isi ike | Ọkwa T | Ọkwa SM |

| 56HRA-62HRA | 595HV200 |

Nke gara aga: API 7-1 Igwe Ọdụdọ Ịkụ Azụ Na-atụgharị Anya Osote: API 7-1 Ntugharị Casing na-adịghị agbanwe agbanwe

Ime ụlọ 703 Building B, Greenland center, Hi-tech development zone Xi'an, China

Ime ụlọ 703 Building B, Greenland center, Hi-tech development zone Xi'an, China 86-13609153141

86-13609153141